6-Axis Turning & Milling

Screw Machining

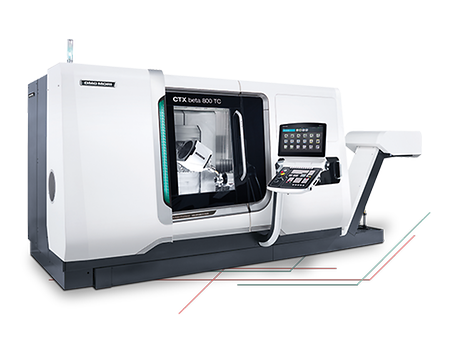

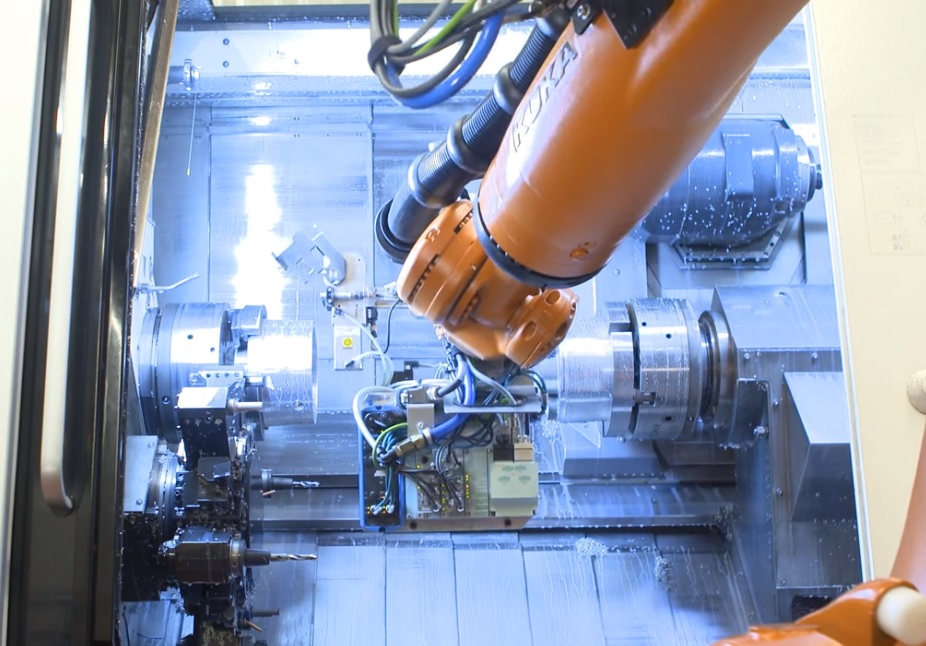

At Metalmite Corporation — a CNC machine shop located in Rochester, Michigan — just outside of Detroit — we use Mori Seiki CNC Lathes with main spindle, programmable sub-spindle, live-tooling and “Y” axes. They are the ultimate in Multi-Tasking lathes. Talk about LEAN machine cells, these machines are like two CNC Lathes back-to-back with a full CNC Machining center mounted on top; all working together towards a common goal, your parts faster, better and cheaper. Raw material goes in and finished parts come out. This virtually eliminates all Non-Value-Added activity in the machining process. No need for multiple fixtures and fixturing, no wait time going from machine to machine, no Batch and Queuing just pure LEAN processing. Every activity performed is continuously moving your part closer to a more finished state. Only VALUE added activities goes into your parts.

At Metalmite Corporation — a CNC machine shop located in Rochester, Michigan — just outside of Detroit — we use Mori Seiki CNC Lathes with main spindle, programmable sub-spindle, live-tooling and “Y” axes. They are the ultimate in Multi-Tasking lathes. Talk about LEAN machine cells, these machines are like two CNC Lathes back-to-back with a full CNC Machining center mounted on top; all working together towards a common goal, your parts faster, better and cheaper. Raw material goes in and finished parts come out. This virtually eliminates all Non-Value-Added activity in the machining process. No need for multiple fixtures and fixturing, no wait time going from machine to machine, no Batch and Queuing just pure LEAN processing. Every activity performed is continuously moving your part closer to a more finished state. Only VALUE added activities goes into your parts.

Today most companies are still trying to figure out the best configuration for setting up their machine cells. At Metalmite we determined the BEST way was Multi-tasking 6-Axis machines. From raw bar stock, your parts are turned on both ends and drilled & milled complete. There is no fixturing and re-fixturing, thus eliminating accumulated stack-up error that otherwise exists in the other’s standard machining practices. Complex parts and shapes, No problem! We can do them all for you. Come see us, we’ll show what we got. Then you’ll be a believer too! We’ll be pulling for you. Choose the right supplier and save money, get higher quality parts and shorter lead-times. The choice is yours.

SIGN UP FOR UPDATES!

Get news from Metalmite Corp. in your inbox.